Updated: 6/30/2014 2:58:38 PM

The 6th session SPINEXPOTM New York will open soon at The Metropolitan Pavilion on July 15th–17th, 2014. The upcoming event will bring to New York a new generation of textile suppliers combining a strong supply chain, international design studios and innovative yarn R&D teams accompanied by consolidated manufacturing and established access to raw materials.

UPW is celebrating its 30th anniversary: as a tight knit team dedicated to developing collections by continually challenging and implementing new initiatives to improve quality and productivity, this is of great significance.

All the manufacturing is done in Dongguan, China where UPW is an important part of the community.

UPW is a very socially responsible company, with a commitment to animal welfare, environmental projects and sustainability.

UPW is one of China’s largest privately owned woolen spun, semi-worsted and fancy twist spinners.

As a large supplier of Cashmere, UPW features Mohair, Alpaca, Angora, Camel and Yak, alongside fine micron wools, premium cotton and silk this season.

Key volume lines are 100% cashmere, 100% extrafine merino, Lambswool/nylon, Cotton/Cashmere and multi-fibre blends with cashmere and alpaca, as well as an extensive range of Donegal yarns.

UPW is well-known for its fantastic colour offer and introduced new qualities into the stock collection, supporting them with ready-to-sample stock. Because UPW offers fully stock supported range, minimum orders are as little as 1 kg per colour.

UPW is very useful to designers and retailers who are looking for a quick response and flexibility for their garment sampling. The vast array of yarns is aimed at mens and womens knitwear, and yarn counts are suitable for 14 gauge to 1.5 gauge.

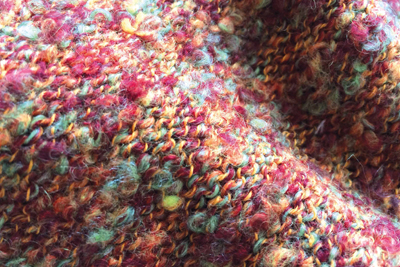

The Fall/Winter 2015/16 collection contains the newest yarns UPW has ever shown! The trend is towards hairier and textured surfaces with hand feels softer and airier than before. Some of the new fancy yarns are made up of the components from core yarns, so even fancy effects are available in the extensive colour offer, providing something new for all sectors of the market.

To discover Stand C10

Established as a subsidiary of Esquel Group in 1991, Guangdong Esquel Specialty Spinning (GES) successfully diversified itself into a specialty spinning mill capable of producing premium and trend-setting products such as “Cashmere like Cotton”, “Eco-cotton” and recycled cotton yarns.

The mill also provides a wide variety of blended yarns including Comerino?, cotton-silk, cotton-cashmere, cotton-yak, cotton-linen, cotton-hemp, as well as cotton-modal, cotton-viscose, etc. Other specialty yarns include budding yarn, ink yarn, siro yarn, slub yarn and homespun yarn.

In recent years, GES has developed unique products that have gained strong momentum in the textile markets. Denim heather yarn and uneven budding yarns are typical items that are worthwhile mentioning:

Esquel’s Denim Heather Yarn is made by GES sophisticated top-dyed spinning technology. It has indigo appearance and color fastness comparable to regular cotton yarn. Heather yarns with a ‘washed’ look/effect are produced in a manner that retains color intensity and substantially avoids the waste of chemicals and water inherent in conventional washing processes thereby making GES denim heather yarn more environmentally friendly.

Uneven Budding Heather Yarn is Esquel’s most popular and bestselling item with a more exquisitely contrasting effect than normal heather. Having an irregular color distribution aspect and sophisticated slub pattern, this effect becomes more evident with a lower yarn count. The yarn also delivers an unrefined stonewash effect on fabric.

Esquel Group strives to be a “green” player by taking innovative initiatives to decrease their carbon footprint, reduce waste, conserve natural resources, and reduce out usage of water and energy while improving efficiency. Upholding the same vision, Esquel Specialty Spinning devotes itself to the development and production of a series of Eco-friendly products under the mission of “Reduce, Reuse and Recycled”.

Esquel Group has evolved into a total services and solutions provider of textiles and apparel, with state-of-the-art production facilities in China, Malaysia, Mauritius, Sri Lanka and Vietnam, and merchandising offices serving key markets in China, Japan, Europe and the USA.

In addition to being a market-oriented and creative yarn provider, GES also strives to be a solution provider by instituting innovative solutions designed for key customers including Ralph Lauren, Tommy Hilfiger, Nike, Hugo Boss, Lacoste and Muji.

Stand C17

Jiangsu Xinfang Science & Technology is a large scale joint-stock company integrating wool washing, combing, wool top treatment, dyeing, spinning, weaving and finishing of woolen fabric and semi-worsted fabric.

Xinfang specializes in Research & Development, manufacturing and marketing of semi-worsted, woolen and special fancy yarns in soft, fluffy and unique styles. Xinfang also produces various kinds of fancy yarns with blends of wool, cashmere, angora, alpaca, camel, mink, yak, linen, ramie, viscose, nylon and polyester and luxurious fibres.

Xinfang supplies knitting yarns for socks, sweaters and wovens.

For the coming Autumn/Winter 2015/16 season, Xinfang is offering new product directions and blends such as “keep warm” fibres, baby alpaca blends, new hand feel developments such as “like dry” and comfortable semi worsted yarns. Xinfang also developed personalized yarns, twistless drafted tape yarns, looped yarns and some jean-like yarns.

Minimum quantities: 2000 lbs/type and 500 lbs per color.

Stand: E05

Knitwear at SPINEXPO

OBO – One by One

The history of OBO has its roots in Italy, where its sister company, based in Carpi, is operating exclusively for the luxury market segment.

OBO prides itself in having inherited part of the Italian knitwear know-how and special attention to quality. The company believes they have a slight advantage thanks to that wealth of experience, proposing the latest trends and developments while always keeping an eye on the small details that a fashion product requires.

Since its inception the company has put quality and creativity at the forefront, highlighting the importance of product development and research. Colors, materials and styles are continuously updated in order to meet market trends and an international clientele.

OBO has:

? A yarn and stitches library

? 4 showrooms to accommodate external guests, access to an archive (reserved for the brands OBO had developed working relationships with) of more than 1000 prototypes and garments developed over the years.

? A sample room with 23 manual machines from 1.5 to 18 GG.

OBO partners with several knitters equipped with Stoll and Shima machines able to develop the most complex stitches and techniques, with dye and print houses using digital printing and embroidery mills, further broadening its offer.

Quantities are 200 pieces per style, 100 pieces per color.

OBO is oriented towards the middle and high end tiers and working with foreign international companies. OBO caters to a variety of clients, from leisure and casual wear to more classic and fashion oriented.

Stand: C22

Teambest is a well-established manufacturer who strives for quality with reasonable prices and believes that communication is the key to success. Teambest sees themselves as their clients’ consultants – working with them, listening to their needs and providing suggestions and recommendations to produce knitwear that is high quality at a competitive price.

They provide their clients with support in creative product design and development, material research (yarns, textures, colors, performance).

Teambest manufactures knitwear from various yarns, ranging from simple cotton to novelty yarns and is capable of a great variety of techniques, including embroidery, embellishments, printing (direct/discharge/burnout), wovens and knits together as well as cut-and-sew boiled wool.

Gauges 3 to 14 GG, minimum order 600 pieces, with 2 colour ways.

Using quantities as a guideline, Teambest welcomes customers with orders of at least 2000 pieces per style, but do not limit in a particular category. They can do both basic styles and fashionable items at competitive pricing and work with large department stores as well as private labels.

Stand: G01

Speed Apparel is a trading company with its own R & D Department that prepares fashion trend information and designs.

Speed Apparel has a yarn library, show rooms, and a trimming and accessories collection on display at the show room. They use Stoll computer knitting machines, Shima Seiki computer knitting machines and Whole Garment ® knitting machines.

Speed Apparel has considerable experience in Intarsia, machine embroidery, beading, digital printing, trimmings with woven or cut & sew fabric, and can knit 3 to 14 GG, with minimum orders of 1000 pieces per style.

Speed Apparel targets mid-to-high price casual wear customers.

Stand: G06

Authority in Charge: China National Textile and Apparel Council (CNTAC)

Sponsor :China Textile Information Center (CTIC)

ISSN 1003-3025 CN11-1714/TS