Updated: 6/12/2014 11:12:22 AM

Yarns are made from different fiber types and weights for the different application purposes. Yarn can be wound by various methods, namely random winding, step precision winding and precision winding. The spindle speed, package format, structure and design, as well as the stroke can be adjusted individually. Colleges and universities are searching for methods to simulate and to convert the density spread within the packages. At present, the winding density [g / l] can be measured with the help of a mathematical formula:

The assumption is that bobbins with the same winding diameter have identical winding densities.

Subject to the existing machines the package formats and designs are inherited in many cases. As a consequence, dyeing technologists are limited in choosing the optimal package format and design due to the surrounding conditions.

|

|

| [Fig.01 different package designs] | [Fig.02 different package designs (allowed by Sonoco Plastics)] |

Consumption of water and hence waste water, chemicals, dyes, electricity, and thermal energy are the main cost factors of dyeing processes. Due to the pre-set winding geometry and winding density, in general the potential for optimization is limited. Therefore, Thies calculates the optimum diameters of the dyeing vessel and the optimum arrangement of the spindles in accordance to the pre-set number of packages per carrier. Then, the same liquor ratio can be ensured within a yarn dyeing factory, even with different batch sizes and different vessel sizes. Consequently, there is no need to adjust the parameter settings.

The concept of the flow reversal system, namely from inside to outside and from outside to inside, is proven and considered to be the best overall design. The new Thies iCone is based on an analysis of the liquor flow. As a result the redesign of the distribution system enables significant savings. The new flow reversal system enables the liquor flow to reach the yarn with minimal losses. Furthermore, it offers a quicker change in direction. An enlarged draining system and the energy-efficient functions (ee functions) allow rapid draining processes at a reduced level of bath entrainments. Consequently, the amount of water for rinsing can be reduced considerably. The liquor will be heated up with the help of a newly developed heating coil system, which it located below the material carrier [Fig.03].

[Fig.03 new heat exchanger]

All in all, these design optimizations lead to a significant reduction of the required space. With regards to the same level of dyeings per time unit, the production output is about 23% per square meter higher than in the established eco bloc series. iCone offers ultra-short-liquor-ratio technology by providing the function DynamicDyeing. For example, at a winding density of 380g /l the liquor ratio is 1:3.6, while the liquor circulates from inside to outside. With regard to the same sample, the liquor ratio is 1:5.6 in a fully flooded vessel.

Considering the overall process, the pre-and after treatment processes (washing, bleaching and rinsing) can be identified as the most time consuming and the most resource allocating phases. An increased number of rinse bathes is used to achieve the required color fastness. Therefore, iCone is equipped with a new function, DynamicRinsing. The purpose of this function is to use the minimum possible liquor amount and reduce the numerous "bath-transitions" during the rinsing phase. Moreover, the function DyeControl can be included in the delivery scope of the iCone by request. DyeControl measures the bath saturation [Fig.05], so that rinsing times and the number of required rinsing baths can be adjusted automatically. The processes attain more transparency and security.

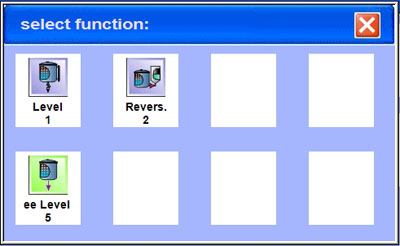

The new ee functions are visually highlighted in green, see [Fig.04].

[Fig.04 ‘ee functions’]

[Fig.05 optimized flushing with DyeControl- dyeing Reactive Navy blue and Marlboro red]

In the case that the requirement is to treat the yarn is with differential pressure, the function FLOWtronic may be helpful. In order to regulate and to control the flow rate within the yarn dye machine, Thies has patented the function FLOWtronic.

The use of the function proVAT is recommended for dyeing cotton with vat dyes. This special feature prevents the penetration of atmospheric oxygen, so that the use of hydraulic and brine can be optimized. The reproducibility can then be increased.

Depending on the color depth time savings of 35 to 60 minutes can be realized. With regard to the overall process time, time savings of up to 12.5%, and electricity savings of up to 11% can be achieved.

Existing material carriers of the eco-bloc series can be used in combination with the new Thies yarn dyeing machine. Vice versa, new material carriers can be linked with existing pressure dryers. There is no need for modifications.

The iCone controller can be equipped with a T858 touch screen monitor for operating the new functions, as well as for the visualization of the process. Controllers can be integrated into a supervisory system for the realization of a higher automation degree.

Authority in Charge: China National Textile and Apparel Council (CNTAC)

Sponsor :China Textile Information Center (CTIC)

ISSN 1003-3025 CN11-1714/TS