![]()

![]()

![]()

![]()

| Textile Machinery Industry Remains in a Downward Trend | |

![]()

| 8 Kinds of Textile Machinery Likely to Be Popular in 2017 | |

|

CHINA TEXTILE LEADER Express is a real-time electronic gazette reporting on the latest news of China textile industry, edited and published by CHINA TEXTILE LEADER, China Textile Information Center. It is the ONLY informative electronic journal that inclusively introduces real-time valuable information of China Textile industry concerning your business and helps you to keep a close eye on China textile industry.

|

Address: China

Textile Information Center, Rm 211, Xiao Yun Building, No.15, Xia Guang Li,

Europe: Italy: North

America:

|

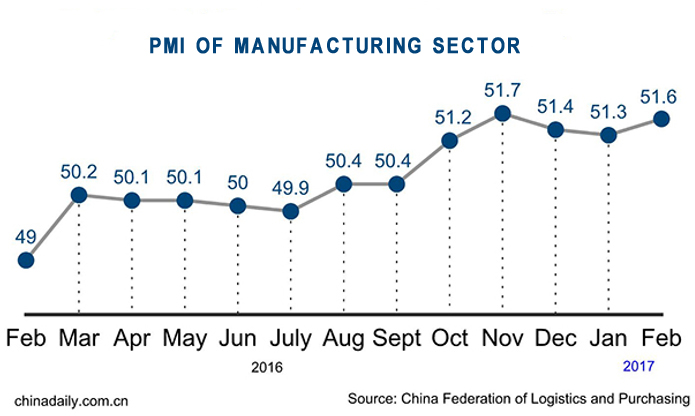

China's Manufacturing Activity Expands for 7th Month

China's manufacturing sector expanded for the seventh month in a row, evidence that the world's second largest economy is stabilizing amid an uncertain global outlook.

The country's manufacturing purchasing managers' index (PMI) came in at 51.6 in February, 0.3 points higher than that recorded in January, according to National Bureau of Statistics (NBS) data released on March 1.

A reading above 50 indicates expansion, while a reading below reflects contraction.

NBS statistician Zhao Qinghe said February's reading remained above 51 for five months in a row and pointed to steady expansion of the manufacturing sector.

The latest reading showed the economy's recent stabilization would continue, said Zhang Liqun, a researcher with the Development Research Center under the State Council.

The Chinese economy started the year strongly, with key economic indicators, including those for trade and inflation, all rebounding.

The country's trade started the year with a strong rebound, with exports and imports both up significantly, despite rising trade protectionism, sluggish overseas demand and increasing domestic production costs.

Meanwhile, China's producer prices rose faster than expected in January while consumer inflation increased, reinforcing views that economic growth is firming.

The sub-index for production was 53.7, 0.6 points higher than that recorded in January.

The sub-index for new orders was up 0.2 points to 53.

Zhao attributed the acceleration of production and new orders to the recovery in market demand and robust production.

In addition, the sub-index for the equipment manufacturing sector expanded to a three-year high of 53.3, 1.7 points higher than the overall manufacturing industry.

Chen Zhongtao, an analyst at the China Logistics Information Center, said positive factors had grown for the Chinese economy, including increasing demand, rising prices, better performance of companies, restructuring and a good job market.

The NBS data showed that the sub index for production and business activities expectation rose for the second month to 60 in February, which indicates enterprises are optimistic about the future.

The Chinese leadership stressed quality in reviving the manufacturing sector, saying the sector should shift from increasing quantity to improving quality.

They said that more energy would be channeled into reducing prices and administrative fees in monopolized sectors as well as lowering business burdens.

A separate survey of the service sector also showed steady growth, with non-manufacturing PMI down 0.4 points to 54.2, but staying above the boom or bust 50-mark for the fifth straight month, according to the NBS.

Railway transport, telecommunication and satellite transmission service, Internet and software information technology, finance and insurance were among the fastest growing service sectors, while retail, road transport, catering and property reported contractions.

The service sector accounted for more than half of China's economy last year and for the majority of growth, as rising income made catering, hotels and travel services more affordable for Chinese consumers.

Cai Jin, deputy head of China Federation of Logistics and Purchasing, said the non-manufacturing PMI pointed to a stable and booming non-manufacturing sector.

China reported 6.7% GDP growth in 2016, lower than in recent years but within the government target range. (Xinhua)

China Consumer Inflation Eases to 0.8% in Feb.

China's consumer price index, a main gauge of inflation, grew 0.8% year-on year-in February, the National Bureau of Statistics (NBS) announced on March 9.

The pace, substantially below market expectation of 1.7%, slowed from a growth of 2.5% in January.

China's producer price index (PPI), which measures costs for goods at the factory gate, rose 7.8% year-on-year in February.

The growth pace quickened from the reading of 6.9% registered in January, according to the NBS. (Xinhua)

China Industrial Output Expands 6.3% for Jan.-Feb.

China's value-added industrial output, an important economic indicator, expanded 6.3% year-on-year in the first two months, compared with the 6-percent increase for December of 2016, official data showed.

The 6.3-percent growth rose from the 5.4-percent increase in the Jan.-Feb. period of 2016. It was also higher than the 6-percent annual gain seen in 2016, according to the National Bureau of Statistics (NBS).

Industrial output, officially called industrial value added, is an important economic indicator. It is used to measure the activity of designated large enterprises with annual turnover of at least CNY 20 million (US$ 2.9 million).

On a monthly basis, industrial production expanded 0.6% in February, the data showed. (Xinhua)

Industrial SOEs See Healthy Gains in 2016

China's State-owned industrial enterprises, which account for the majority of China's SOEs, ended two years of losses in 2016 and reaped good returns on the back of structural optimization.

In 2016, the profits of State-owned industrial enterprises rose 6.7%, the highest growth rate since 2012, according to the State-owned Assets Supervision and Administration Commission.

Profits are no longer limited to traditional industries including oil and coal, with more sectors reporting increasing profits and restored growth, such as pharmaceuticals, electrical machinery and equipment.

"SOEs are making steady progress benefiting from the supply-side structural reform," said Shen Ying, chief accountant of the SASAC.

"Resources are flowing into the more competitive enterprises, helping revitalize their stock and optimizing the efficiency of resource allocation."

SOEs under central government control reported CNY 1.9 trillion (US$ 276 billion) in revenue in January, an 8.7-percent year-on-year increase. The total profit reached CNY 89.12 billion, 24.5% higher than the same period last year.

Compared with the past, when SOE's profits were limited to a few sectors including oil, power and coal, the profits are more balanced and well distributed, with profits from electronic equipment, electrical machinery, medicine and wine, beverages and refined tea reaching CNY 165.6 billion (US$ 241.1 billion), accounting for 14.1% of the total, up 2.5% year-on-year.

SOEs in coal, power, oil exploration and processing accounted for 35.3% of the total profits, an 8.3-percent decrease year-on-year, as well as the fourth consecutive year of decrease.

On the other hand, manufacturing has become the major profit source, which earned CNY 839.3 billion in 2016, a year-on-year increase of 36.2%, the fourth consecutive year of growth since 2013, with advanced manufacturing sectors including electronic equipment, electrical and mechanical, pharmaceutical having substantially improved in the past three years.

In addition to SOEs under the central government, locally administered SOEs also reported growing profit, the government said.

In 2016, the SASAC promoted the reorganization and integration of 10 State-owned enterprises, including Baosteel and Wuhan Iron and Steel Co, and the number of enterprises supervised by SASAC has also been reduced to 102.

China COSCO Shipping Corporation Ltd said it has achieved a profit growth of nearly 8% year-on-year with operating costs dropping significantly, greatly increasing the competitiveness in the global shipping market.

Analyst said the SOE's ending profit losses and restructured profit shares are due to China's constant upgrading of the economic structure and innovation, keeping economic growth at a reasonable range and raising growth quality and efficiency. (chinadaily.com)

China to More Briskly Introduce Foreign Investment: Minister

China will more briskly introduce foreign investment, Commerce Minister Zhong Shan said.

Addressing a meeting in Beijing, Zhong promised more efforts in the area this year, including propelling the development of free trade zones, pushing for reforms in foreign investment management, and improving the business environment.

Foreign direct investment on the Chinese mainland rose 4.1% year-on-year last year, mildly down from the 6.4-percent gain in 2015.

China has been loosening the grip on the inflow of foreign capital as part of efforts to facilitate its opening up, reducing restrictive measures and opening more sectors. In 2016, laws on foreign investment were amended, and measures were unveiled to simplify the approval procedure for foreign companies.

Zhong also hopes foreign-funded businesses will play a bigger role in boosting China's sluggish real economy.

Foreign companies generate nearly half of China's foreign trade, 20% of tax incomes and a seventh of urban jobs during the past four years, he said.

Zhong was appointed Commerce Minister, replacing Gao Hucheng, the top legislature said. (Xinhua)

China Sets 2017 GDP Growth Target at around 6.5%

China has set its GDP growth target at around 6.5% for 2017, compared with a target range of 6.5-7% for 2016, according to a government work report available to the media on March 5. (Xinhua)

China to Keep Consumer Inflation at around 3%

China aims to keep consumer inflation at around 3% in 2017, according to a government work report available to the media ahead of the annual parliamentary session.

The country's consumer price index rose 2% last year. (Xinhua)

Xinjiang to Invest over CNY 72 Billion in Textile and Garment Industry

It is revealed on the meeting for promoting the development of textile and industry to boost employment recently held by Xinjiang Uygur Autonomous Region that in 2017, Xinjiang will invest more than CNY 72 billion in the fixed assets of local textile and garment industry, up more than 50% year-on-year, offer 100,000 job opportunities, increase industrial value added by over 40% and take over more than 400 enterprises transferred from inner land.

Over the past three years, the textile and garment industry in Xinjiang has invested near CNY 90 billion in fixed assets, installed 13.60 million spindles and a garment processing capacity of 150 million pieces per year. Last year, the industry's fixed-asset investment saw 50.9-percent growth to CNY 47.97 billion, an increase of CNY 16.18 billion from 2015, offered 111,800 new jobs, up 15.7%. Both investment and new employment reached the goal set at the beginning of the year. Many indicators hit historical record, some indicators such as the number of cotton spindle and new employment reached the goals of the first-phase development program one year ahead set by the State Council.

Ningxia to Forge World-class Textile Industrial Cluster

The Municipal Government of Yichuan, capital city of Ningxia Hui Autonomous Region and China National Textile and Apparel Council (CNTAC) recently held a ceremony in Beijing for launching the National Smart Textile Base in Yichuan. Based on Ningdong Energy Sources and Chemical Industrial Base, which will play a role in connecting the textile chain and by taking the opportunities of forging a national smart city, Ningxia will build a world-class textile industrial cluster with annual industrial output reaching CNY 100 billion.

Ningxia is an important raw cashmere production base and distributing center with annual trade volume of raw cashmere up to 12,000 tons, accounting for over 65% of the world total. With an annual cashmere dehairing capacity of 13,000 tons, it produces 8,000 tons of dehaired cashmere, ranking first in the world. With Yinchuan comprehensive bonded area in operation, cotton and certain chemical fiber raw materials have been exempted from multiple tariffs, making Yinchuan a more attractive place for investors.

At present, Yinchuan has attracted several large-sized well-known textile enterprises including Zhongyin Cashmere, China Hi-tech, Shandong Ruyi and Shandong Hengfeng. Meanwhile, Yinchuan has set up 10 billion yuan textile industry development fund; it helped Shandong Ruyi set up financing platform, by which Yuyi is possible to invest CNY 1.1 billion to hold controlling share in the Japanese Renown Company and acquire a number of well-known international entry-lux brands.

In accordance with the "Development Programme of Textile Industry, 2016-2020" published by the Ministry of Industry and Information Technology, Ningxia will promote intelligent manufacturing and green manufacturing of textile industry, establish an innovation-driven development mode by improving product quality and brand influence and enhancing international cooperation, and with the support of Internet, big data and cloud computing technology, it will set up a digitalized, Internet-based and smart manufacturing demonstration base.

Ningxia Eco-textile Industrial Demonstration Park is next to Ningdong Energy Sources and Chemical Industrial Base. The two will complete the textile chain, share resources and complement each other. Ningxia will continue to extend cashmere, cotton spinning and chemical fiber industrial chains by connecting coal chemical and petrochemical production in upper stream while extending to garment and home-textiles production in downstream. By 2020, the scale of Ningxia's textile industry is expected to reach near CNY 200 billion, with annual industrial output of CNY 70 billion.

Shaoxing Carries out Special Campaign for Promoting Transformation and Upgrading of Traditional Industries

Shaoxing in Zhejiang Province recently deployed special campaign on eliminating outdated printing and dyeing capacity. It will take four actions, namely promoting agglomeration of printing & dyeing industry, regulating the chemical industry, upgrading industrial parks (areas) and undertaking ultra-low emission reform of thermo power plants.

Printing & dyeing industry and chemical industry are traditional competitive industries in Shaoxing, accounting for around 22% of the local industries (calculated on the basis of major enterprises each with annual turnover more than CNY 20 million). They are the main source of industrial pollution. This time, 182 printing & dyeing enterprises and 190 chemical enterprises are put in the list of eliminating outdated capacities, in which, 20 printing & dyeing enterprises and 21 chemical enterprises are asked to shut down or stop production within this year, while 130 printing & dyeing enterprises and 141 chemical enterprises to go through overhaul and upgrading. In addition, Shaoxing has set up goal for fostering bigger and stronger printing & dyeing and chemical enterprises: the printing & dyeing industry and the chemical industry each should cultivate 20 big enterprises each with annual industrial output of more than CNY 1 billion and each introducing a new company into the stock market.

Moving to industrial clusters is an important means for promoting integral upgrading of local industries. In 2017, 32 Keqiao-based printing & dyeing enterprises will move to Binhai printing & dyeing industrial cluster and 21 Shangyu-based chemical industrial enterprises will move to Shangyu Economic Development Zone in Hangzhou Bay.

Goals and tasks have been set for 2017. By the end of 2017, 46 printing & dyeing enterprises in Keqiao District will move to industrial clusters or shut down, 4 printing & dyeing enterprises in Yuecheng District will shut down and two printing & dyeing enterprises in Paojiang Development Area will move to Binhai industrial cluster.

During carrying out the campaign, Shaoxing will also regulate and upgrade the existing 452 industrial parks (areas). 48 will be shut down, while 404 will be regulated and upgraded.

By the end of this year, 26 thermo power plants should complete the reform of clean, high-efficient and IT-based production, so as to realize ultra-low emission.

Textile Machinery Industry Remains in a Downward Trend

In January-December of 2016, China's textile machinery industry earned prime business revenue of CNY 115.85 billion, up 0.51% year-on-year; total profits CNY 7.83 billion, up 8.73%. In 2016, China's import and export of textile machinery totaled US$ 5.55 billion, down 8.08%.

In January-December, 2016, the total profits of the textile machinery industry amounted to CNY 7.83 billion, up 8.73% year-on-year; the deficit of loss-making enterprises amounted to CNY 605 million, down 25.78%; 13.44% of the major enterprises operated in red. In the same period, the industry's fixed-asset investment totaled CNY 29.92 billion, up 10.74%, accounting for 2.33% of the textile industry's total, 10.43 percentage points higher than in 2015. The total costs and expenses totaled CNY 108.76 billion, up 0.24%.

According to the General Administration of the Customs, in January-December of 2016, China's import and export of textile machinery totaled US$ 5.55 billion, down 8.08% from 2015, in which, the export declined 3.54% to US$ 2.98 billion, the import dropped by 12.84% to US$ 2.57 billion.

China imported US$ 2.57 billion worth of textile machinery from 65 countries and regions, down 12.84% from a year earlier. By product category, the import of auxiliary equipment & spare parts ranked first, amounting to US$ 587 million, up 4.11%, accounting for 22.84% of the total import. Among the seven major categories, only the import of auxiliary equipment & spare parts, nonwoven machinery and knitted machinery presented positive growth by 4.11%, 2.21% and 5.81%, respectively. The imported textile machinery mainly came from Germany, Japan, Italy, Belgium and Taiwan. The import from these five suppliers totaled US$ 2.06 billion, down 16.03% from a year earlier, accounting for 80.15% of the total import in value term.

In January-December of 2016, China exported US$ 2.98 billion worth of textile machinery, down 3.54% from a year earlier. By product category, the export of knitting machinery occupied the first place, amounting to US$ 920 million, up 0.77% year-on-year, accounting for 30.88% of the total export value. It is followed by printing, dyeing & finishing machinery, auxiliary equipment & spare parts, spinning machinery, weaving machinery, chemical fiber machinery and nonwoven machinery. The export of weaving machinery registered the biggest decline of 28.90%. China exported textile machinery to 178 countries and regions around the world. The total five destinations include India, Bangladesh, Vietnam, Pakistan and Indonesia, whose imports accounted for 53.31% of the total export value. The export to India amounted to US$ 609 million, down 2.38% year-on-year, accounting for 20.42% of the total export value.

In 2016, the textile machinery industry maintained a downward trend, with various indicators wavering at low level, both import and export declined in value term. In 2017, the industry is predicted to remain under downward pressure due to uncertainties of external environment.

8 Kinds of Textile Machinery Likely to Be Popular in 2017

In 2017, under marketing pressure from both home and abroad, the textile industry will continue its supply-side structural reform. Under such background, it is impossible to maintain the sales growth of textile machinery by relying on scale growth. For textile machinery industry, variety and quality are what its customers more care for.

8 kinds of textile machines may become bestsellers in 2017, according to a report published by China Textile News.

The first is roving-spinning unit. The biggest advantages of such system is labor saving. Over the past few years, many suppliers of roving-spinning unit and spinning-winding unit have seen significant growth in both production and sales. Under the current situation of recruitment difficulty and increasing labor cost, roving-spinning unit is expected to maintain its position as a bestseller on market in 2017.

The second is compact spinning unit. Compact-spun yarn has reduced hairiness. Fabric woven with compact-spun yarn has better air permeability and smoother surface than the fabric woven with conventional yarn in same warp and weft density. Compact-spun yarn, when being used in knitting, can significantly reduce breakage, and when being used in yarn-dyed weaving, can reduce weft-wise slub, thus improving fabric surface. Many enterprises have applied compact spinning technology in producing blended yarn containing bast fiber, polyester fiber and cool fiber, etc., aimed at improving the functions and styles of fabric. Despite the poor operation of the textile economy, users pose increasing requirements on yarn quality, while compact-spun yarn is just the right choice for meeting the requirement.

In the first three quarters of 2016, about 4.2 million spindles (including retrofitting) of compact spinning unit were sold, up 90.3% year-on-year.

The next possible bestseller is long spinning frame with integrated doffing, which has been sold well over the past few years thanks to a number of advantages such as labor-saving and high automation level. As many Chinese textile enterprises are facing recruitment difficulty, such machine can meet their needs for enhancing productivity and reducing labor. Despite the difficult situation confronted by the textile industry, some competitive enterprises continue to expand their production scale. When buying new machines, they give first consideration to long spinning frame. They have played certain role in guiding the buying tendency of the industry.

Related figures show that in the first three quarters of 2016, China sold 2.97 million spindles of cotton spinning frames, up 14.23% year-on-year, including 1.84 million spindles of long spinning frame, up 67.27%. Long spinning frames make up 61.90% of the installed spinning capacity, 19.65 percentage points higher than in the same period of 2015. As automatic and manless machines will become the dominant trend, long spinning frame is expected to have a good market.

Another bestseller on the textile machinery market in 2017 will be water-jet loom. Water-jet loom can turn out diversified products. It is especially suitable for weaving synthetic filament fabric, from coarse to fine deniers, from narrow to wide width, from plain fabric to jacquard fabric and specific fabric. Compared with other looms, water-jet loom is superior in terms of average weft insertion and productivity. Water-jet loom is suitable for small-lot and diversified production and the initial investment is low. The fast growth in the demand for synthetic fabric has provided large room for the rapid development of water-jet loom. Water-jet looms cover high share in filament weaving sector. The rapid development of the filament weaving sector over the past few years has also promoted the sale growth of water-jet loom. In the January-September period of 2016, China imported 849 sets of water-jet looms, up 21.98% year-on-year; totally 16,000 water-jet looms were sold on domestic market, up 14.29%.

Digital printer will be the next bestseller. Digital printing is based on direct printing, which can effectively avoid material and water waste and pollution, which often happen in the screen-making stage in conventional printing process. Thanks to its high register precision, digital printing can basically avoid the several hundred meters of fabric waste before perfect register of manual operation. Meanwhile, new digital printing machine can effectively reduce energy consumption and pollution.

With the improvement of technology, high-speed digital printer is almost as fast as flat-screen printing machine, while at the same time it can reduce production costs. Experts predict that by 2019, 7.2% of the printed fabric will be produced on digital printer in China.

The next bestseller is low-bath ratio and energy-saving dyeing machine. With the rapid development of knitted fabric market, low-bath ratio overflow dyeing machine, energy-saving airflow dyeing machine and air-liquid dyeing machine have become main products of machinery manufacturers. Water-saving, high-efficiency continuous pre-treatment machines and knitted fabric finishing machines have been popular on market over the past few years. Such trend is expected to continue in 2017.

The seventh bestseller will be fully-fashioned flat knitting machine. As consumers pursuit personalized and high-quality products, fully-fashioned flat knitting machine and "knit-and-wear" technology have gained popularity. With simple and fast operation, it can turn out diversified and value-added products. This not only can satisfy consumers' pursuit for personalization, but also prevent the products from being sold at excessive price through various distributors, help producers cut down inventory cost and shorten the product circulation process from producer to consumer.

The last product likely to become bestseller in 2017 is spunlace nonwoven fabric line. Nonwoven fabrics are developing towards becoming alternative of woven and knitted fabrics. Spunlaced nonwoven fabric is the most potential product that can compete with textile fabric for its similarity to textiles, excellent physical properties as well as high quality and reasonable price.

In the first three quarters of 2016, about 30 spunlace lines were sold on Chinese market. Also, around 50 spun-bonded and SMS lines were sold. German and French machinery manufacturers also reported their good performance in 2016. Most nonwoven fabric machinery manufacturers hold optimistic attitude towards sales situation in 2017.

![]()

CHINA TEXTILE LEADER (CTL), renowned monthly journal focusing on worldwide technological development across all sectors of the textile industry, is published by the Consultation & Publication Department of China Textile Information Center with its first publishing in the year 1965. Since after the born of CTL, persistent study on China textile industry never ceased. Over the years that passed, we have gathered in our hand with four distinguished business units.

![]()

CHINA TEXTILE LEADER

CHINA TEXTILE LEADER (CTL) is a monthly

journal focusing on worldwide technological development across all sectors

of the textile industry; the sole steering publication in Chinese textile

circle created to help industry and enterprise decision-makers interpret

technological policies and industry regulations, keep them informed of the

development trend of both technology and market; and a worldwide respected

media offering a platform for textile industry insiders to exchange ideas

and share the information about major events in the global textile

industry.

CHINA TEXTILE LEADER (CTL) is a monthly

journal focusing on worldwide technological development across all sectors

of the textile industry; the sole steering publication in Chinese textile

circle created to help industry and enterprise decision-makers interpret

technological policies and industry regulations, keep them informed of the

development trend of both technology and market; and a worldwide respected

media offering a platform for textile industry insiders to exchange ideas

and share the information about major events in the global textile

industry.

Mission: Pay Close Attention to the Advancement of Textile Technology; Help Enterprises Increase Their Fortune.

Aims: To advocate textile technological innovation; to report on advanced applicable technology; to give guidance to enterprises in product development; to provide a communication channel.

Contents: Cover the entire textile chain from fiber processing, spinning, weaving, knitting to dyeing & finishing, nonwovens, technical textiles, home textiles, apparel, textile machinery and marketing.

Click here www.texleader.com.cn/en to know more.

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

CHINA TEXTILE LEADER Express (CTL Express) is a real-time electronic gazette reporting on the latest news of China textile industry, edited and published by CHINA TEXTILE LEADER, China Textile Information Center (CTIC). It is an informative electronic journal that inclusively introduces real-time valuable information of China Textile industry encapsulating five major parts: In-depth reading of macro policies covering economy, industry, trade, fiscal and finance, operating performance investigation of textile industry and specific subsectors, technological advancement and product R&D progress report, fixed asset investment research. By relying on the comprehensive, accurate and timely information resource of CTIC and an authoritative editing team, CTL Express welcomes the subscription of all global textile professionals.

Click here http://www.texleader.com.cn/en/Subscription%20CTLExpress.asp to subscribe

*******************************************************************************************************

Information Consultation Services

Consultation & Publication Department of China Textile Information Center (CTIC), by relying on the

prodigious information resource, preeminent experts team and rich

industrial experience of the CTIC, provides professional, objective and

accurate information consultation services in an array of specific textile

arenas including technological progress research, textiles related

consumption analysis, investment strategy investigation, industry

orientation research, supply chain analysis and project feasibility

studies.

Consultation & Publication Department of China Textile Information Center (CTIC), by relying on the

prodigious information resource, preeminent experts team and rich

industrial experience of the CTIC, provides professional, objective and

accurate information consultation services in an array of specific textile

arenas including technological progress research, textiles related

consumption analysis, investment strategy investigation, industry

orientation research, supply chain analysis and project feasibility

studies.

Specific

Consultation Services:

Status quo and Development Orientation

Research of Specific Sectors of China Textile Industry;

Practitioners

Survey of Specific Sectors of China Textile Industry;

Policy, Guideline

and Regulation Study of Specific Sectors of China Textile

Industry;

Strategic Investment Investigation on Specific Sectors of

China Textile Industry;

End-use Market Survey of Varied Textile

Products;

In-depth Study on the Specific Sectors of China Textile

Industry.

You can email to songfujia@texleader.com.cn or info@texleader.com.cn for consultation services.

*******************************************************************************************************

The most inclusive China textile industry

database

The most inclusive China textile industry

database

After years of unwavering commitment, our database

now encapsulates almost all domestic companies engaging in textile

industry with subsectors including chemical fiber, spinning, weaving &

knitting, garment-making, dyeing and finishing, technical textiles, home

textiles, textile machinery as well as international trade. All essential

company information are under careful and timely maintenance enabling us

adequately competent at rendering accurate and efficient database

marketing services to both domestic and offshore customers.

Effective

propaganda material directly delivered to latent clients

Advertisement

dissemination via massive E-mail sending

Online advertising at CTL

E-alert

You can email to info@texleader.com.cn or aiming@texleader.com.cn for e-mail marketing services.